A Visit to the CPSC Lab in 2013

Summary: CPSC opened their new National Product Testing and Evaluation Center in Rockville, Maryland, in 2011. In this location the Commission performs all compliance testing for its bicycle helmet standard. We visited in February of 2013 with a lab tour sponsored by the International Consumer Product Safety Organization.

The building was constructed by Craig Venter for the first

private-sector Human Genome Project. It has excellent infrastructure for labs, including one-time air use exhaust

systems, a huge backup UPS in case the mains electric power goes off and a full-load generator to take over from the UPS.

CPSC gutted the interior for its own type of labs. They added hard rooms for fireworks storage and two fire-resistant

rooms outside the original external walls for flammability testing. It is an impressive facility, with large, clean labs

and a lot of updated equipment. Note than any samples seen in these photos are not related to actual current

compliance tests, and very unlikely to have been involved in any sensitive CPSC actions. The labs get many visitors, so

products currently under investigation for defects are stored.

The building was constructed by Craig Venter for the first

private-sector Human Genome Project. It has excellent infrastructure for labs, including one-time air use exhaust

systems, a huge backup UPS in case the mains electric power goes off and a full-load generator to take over from the UPS.

CPSC gutted the interior for its own type of labs. They added hard rooms for fireworks storage and two fire-resistant

rooms outside the original external walls for flammability testing. It is an impressive facility, with large, clean labs

and a lot of updated equipment. Note than any samples seen in these photos are not related to actual current

compliance tests, and very unlikely to have been involved in any sensitive CPSC actions. The labs get many visitors, so

products currently under investigation for defects are stored.  Visitors are briefed by Andy Stadnick, CPSC's Director of Laboratory Sciences.

Visitors are briefed by Andy Stadnick, CPSC's Director of Laboratory Sciences.  The helmet test lab, located with equipment for other types of

testing.

The helmet test lab, located with equipment for other types of

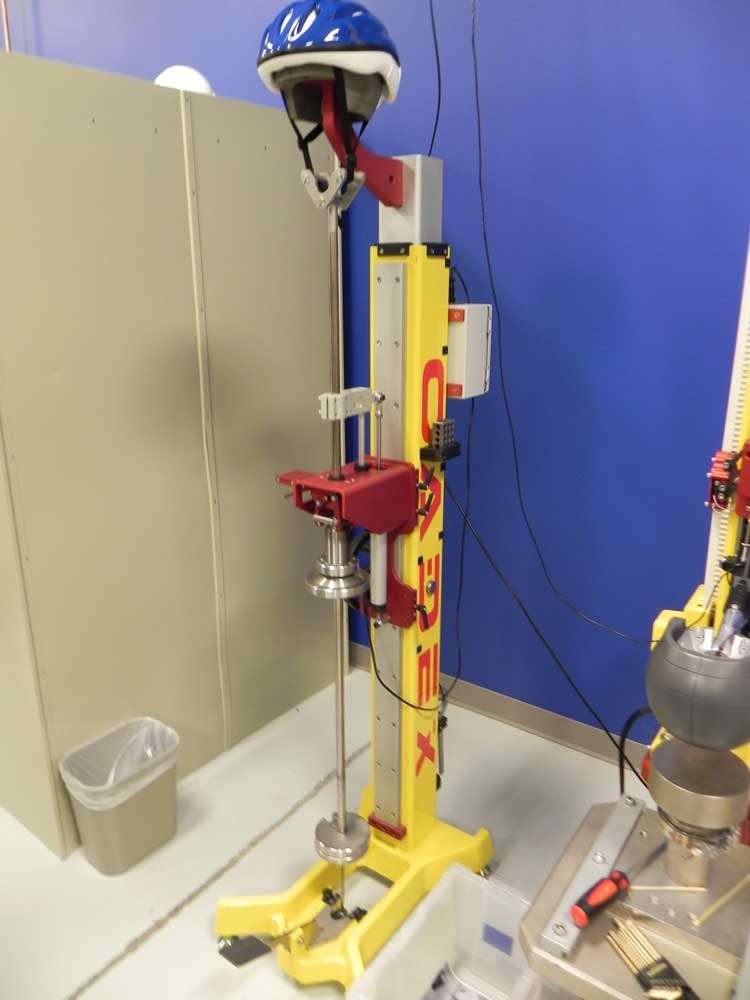

testing.  The lab got updated test equipment in the new lab

building. From left, the data acquisition area, dynamic strap strength test machine, monorail drop rig, old and no longer

used drop rig, and the edge of the table used to mark test lines on the helmets before impact testing.

The lab got updated test equipment in the new lab

building. From left, the data acquisition area, dynamic strap strength test machine, monorail drop rig, old and no longer

used drop rig, and the edge of the table used to mark test lines on the helmets before impact testing.

The monorail test rig was supplied by CADEX of Canada. Data acquisition is from Biokinetics, another Canadian supplier. A helmet is placed on an instrumented headform, helmet down, and dropped a measured distance onto a steel anvil. Instruments in the headform feed g data to the data acquisition system on the left. Drop heights for the CPSC standard are 1 meter on the hemispheric and curbstone anvils, and two meters on the flat anvil.

This machine tests strap stretch and strength when jerked with a dynamic load.

The lab compares well with others we have seen. The staff has a thorough understanding of the test protocols and applies them conscientiously. CPSC staffer Ian Hall briefs a group on how the lab functions.

The lab has an area with equipment for marking helmets. The test lines must be precisely marked before a helmet can be tested. Technicians can rotate the headform and helmet to aim impact sites anywhere above the test line.

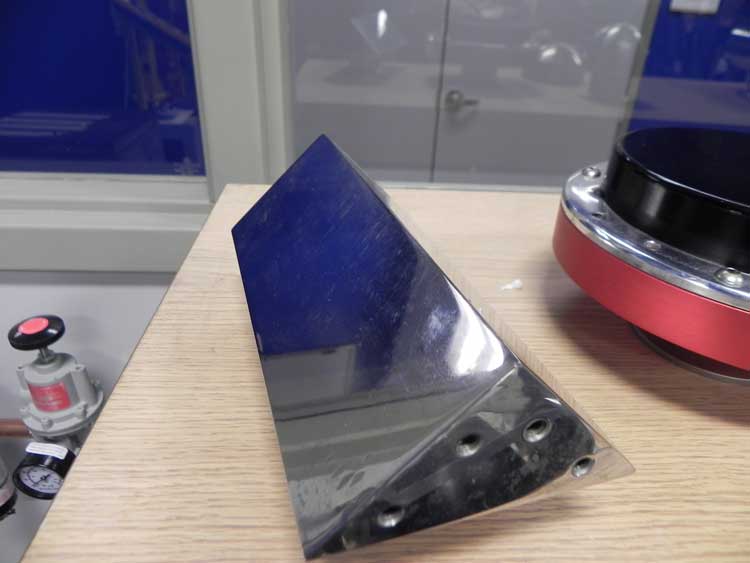

The lab Headforms and anvils came from CADEX. The earlier anvils are chromed, but the most recent have a satin finish, providing a slightly less stringent test, particularly on wet samples.

Anvils

Current satin finish curbstone anvil.

This machine attempts to pull the helmet off with a calibrated yank, to show the efficacy of the retention system, in what is called a rolloff test.

Our conclusion: after a tour of the lab and a briefing from the staff, we have confidence in the validity of CPSC's helmet test results. These photos were taken on February 26, 2013.

Here is a tour of the old CPSC lab, done a decade earlier in 2003.

Back to the top

Back to the Home Page